Shenzhen Jawin Media Electronics Co.Ltd

A Trusted Copy & Test Solution Partner for Southeast Asian Factories.

- Home

-

About JMEGA

About JMEGAWe are Your

Trusted PartnerA Trusted Copy & Test Solution Partner for Southeast Asian Fact. -

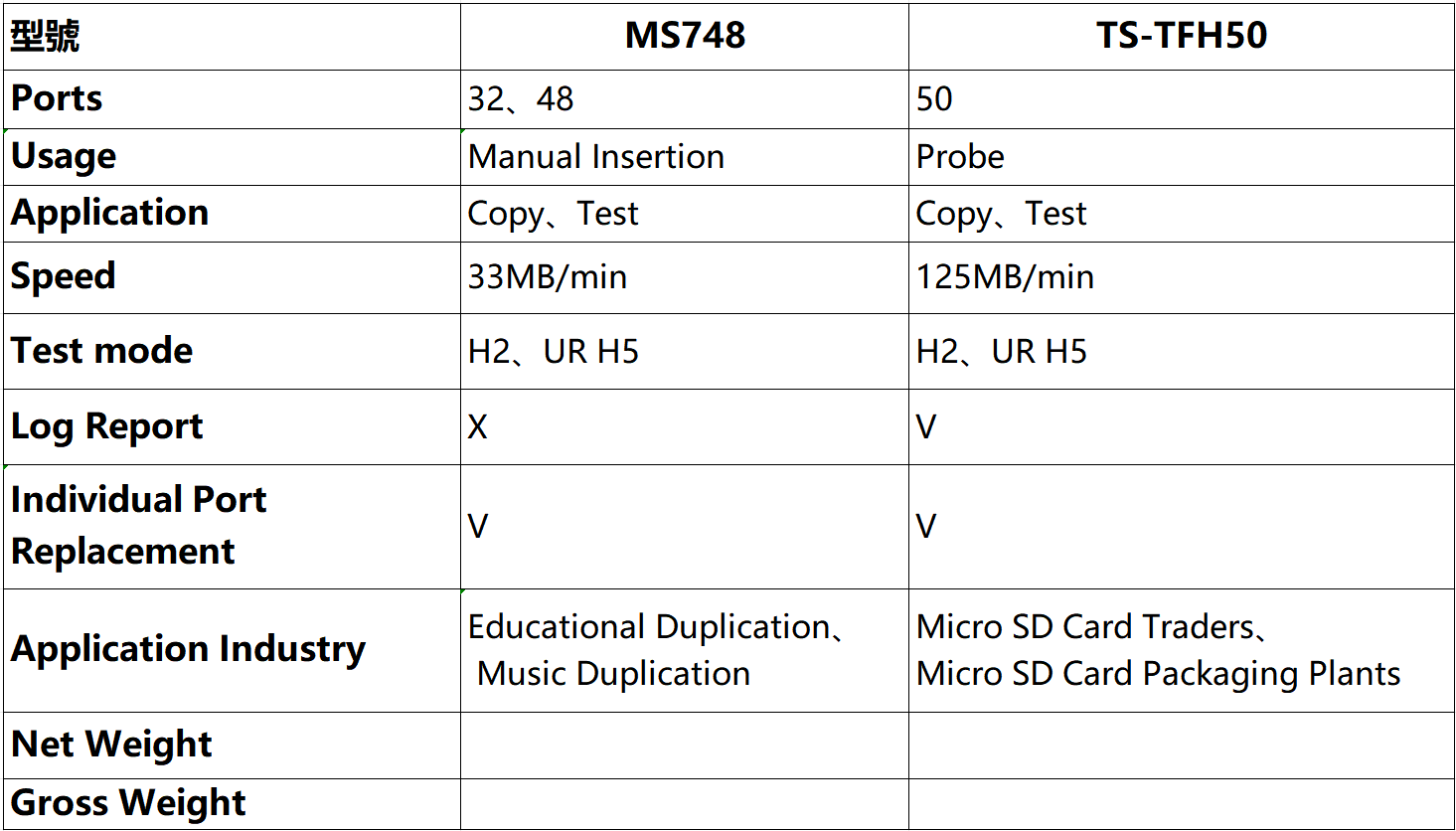

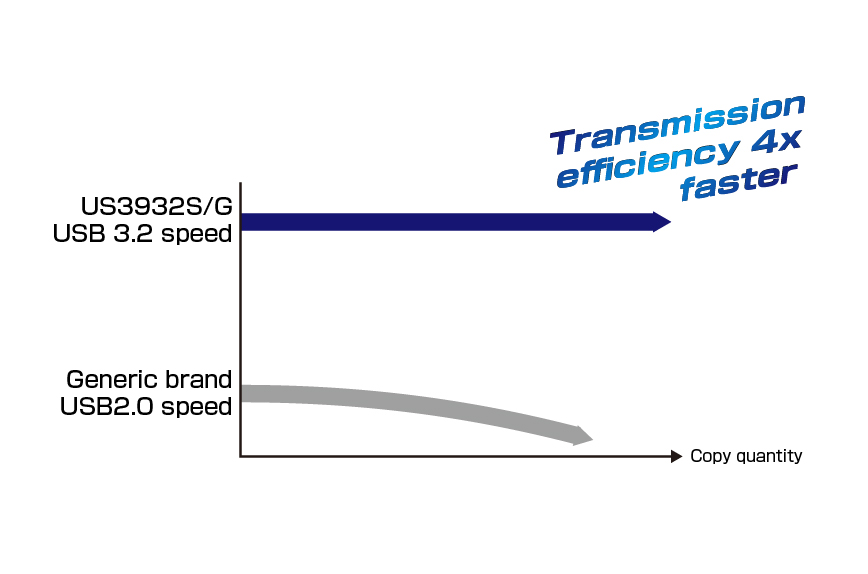

Duplicator

Products CategoryFind the

Right ProductWe Provide Efficient, High-Precision, and Highly Stable Industrial Grade Equipment. -

Interface Test Equipment

Interface Test EquipmentWe are Your

Trusted PartnerA Trusted Copy & Test Solution Partner for Southeast Asian Fact. -

Case Studies

Case StudiesWe are Your

Trusted PartnerA Trusted Copy & Test Solution Partner for Southeast Asian Fact. - Contact Us